Toll Free: 1800 419 3356

| Model | P 365 DC09 | P 400 DC13 | |

|---|---|---|---|

| Power rating | kVA / kWe | 365/292 | 400/320 |

| Duty | PRIME | ||

| Power Factor | 0.8 lagging | ||

| Output Voltage | Volts | 415 | |

| Output Frequency | Hz | 50 | |

| No. of phases | 3 | ||

| Full load Current | Ampere | 507 | 556 |

| RPM | 1500 | ||

| Overall Dimensions of the genset (l x w x h) | mm | 5000 x 1800 x 2200 | 5700 x 2100 x 2400 |

| Approximate Weight | kg | 5300 | 6400 |

| Acoustic Canopy | 6 sided, container type, Bottom Lifting, made out of 100 mm steel CRCA sheets, rockwool insulated with residential silencer and specially designed for increased service accessabilty. | ||

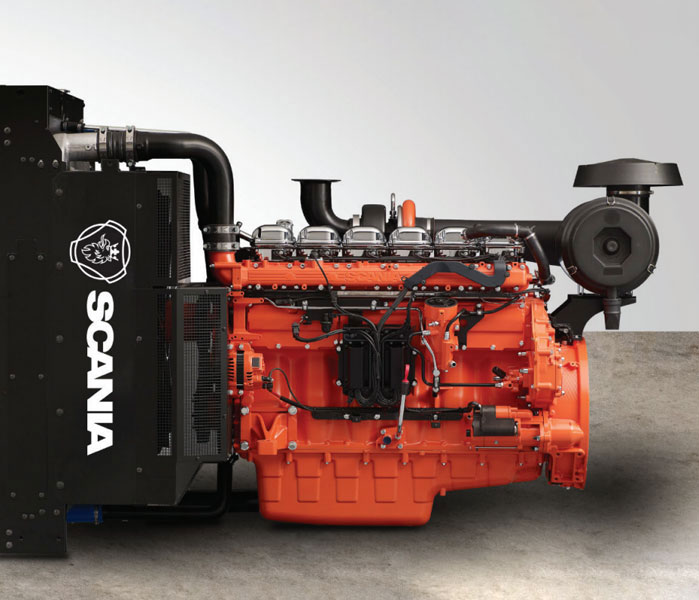

| Model | DC09 071A | DC13 071A | |

|---|---|---|---|

| No. of Cylinders | Qty | 5 | 6 |

| Gross Engine bhp | hp | 430.2 | 494.6 |

| No. of Stroke | 4 Stroke | ||

| Bore | mm | 130 | |

| Stroke | mm | 140 | |

| Displacement | cc | 9300 | 12736 |

| Alternator | 400 kW / 320 kW | ||

| Compression Ratio | 16:01 | ||

| Direction of Rotation from Flywheel end | Counter clock wise | ||

| Reference Standard | REF | ISO 8528-5 G2 | |

| Governing system | Scania engine management system, EMS | ||

| Starting Battery Volts | Volts | 24 V | |

| Engine Cooling System Coolant Capacity | Litres | 24 | |

| Cooling Capacity Including Radiator | Litres | 38 | |

| Coolant topping-up / draining frequency | 7200 hrs, Only with the use of Scania Genuine Coolant. Draining at 6000 hrs for others. Both within 5years or whichever is earlier | ||

| Engine Mounted Radiator Fan Power | kW | 6 | 10 |

| Fuel System | Scania Unit Injection, PDE | ||

| Filter Type | Paper filter element, 10 micron | ||

| No. of filters | qty | 1 | |

| Lub Oil system capacity (with filters) | Litres | 36 | 45 |

| Lube Oil Change Period | Hours | 600 hours with use of Scania LDF-3, otherwise 500hrs with approved Oils | |

Parameters can be displayed with required shut off system

| Power rating | kVA / kWe | 365/292 | 365/292 |

|---|---|---|---|

| Power Factor | 0.8 lagging | ||

| No. of phases | 3 | ||

| Output Frequency | Hz | 50 | |

| RPM | 1500 | ||

| Output Voltage | Volts | 415 | |

| Voltage Variation | % RV | 5% | |

| Full load Current (Rated) | Ampere | 507 | 556 |

| Enclosure | IS: 4691 | IP 23 | |

| Cooling | IS: 6362 | IC 01 | |

| Insulation Class | H | ||

| Excitation Type | Self Exciter and Self regulated Brushless | ||

| Voltage regulation | +/- 0.5% From no load to full load at lagging power factor of 0.1 to 1.0 & speed drop of less than or equal to 4% | ||

| Overload Capacity | 1.5 x Rated Full Load Current for 15sec or 1hr in every 12 hr with 10% overload | ||

| Unbalanced Load Permitted | 20% (Not exceeding Rated FLC in any phase) | ||

Fuel tank with all internal piping and Standard Control Panel with all internal wiring and cabling provided as a standard scope of supply. For requirement of AMF control panel or synchronisation panels or any special panels, please contact us.